Advanced Sugarcane Bagasse Pulp Coating Production Line for Eco-Friendly Molding Solutions

商品の詳細:

| 起源の場所: | 中国 |

| ブランド名: | Osmanuv |

| 証明: | ISO9001 |

| モデル番号: | OSM-XT-1024 |

| ドキュメント: | PULP MOLDING AUTOMATIC SPIN...NE.pdf |

お支払配送条件:

| 最小注文数量: | 1セット |

|---|---|

| 価格: | 交渉可能 |

| パッケージの詳細: | 木製の箱 |

| 受渡し時間: | 45日 |

| 支払条件: | T/T |

| 供給の能力: | 交渉 |

|

詳細情報 |

|||

| コーティング効率: | 高効率 | 状態: | 今から |

|---|---|---|---|

| 噴霧室: | 304ステンレス鋼 | パッケージ: | 木製のケース |

| 塗装の使用法の使用: | 100% | ランプタイプ: | 炭素繊維タイプ |

| 機械名: | スピンコーティング機械 | パッキング: | 標準の木製ケース |

| ハイライト: | sugarcane bagasse pulp coating line,eco-friendly pulp molding machine,pulp molding coating production line |

||

製品の説明

Advanced Sugarcane Bagasse Pulp Coating Production Line for Eco-Friendly Molding Solutions

Composition of Production Line:

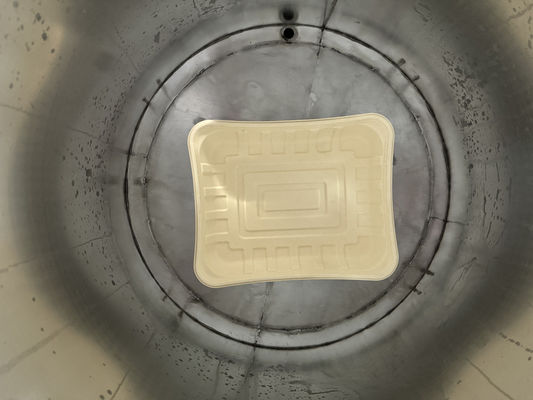

This versatile production line utilizes sugarcane bagasse pulp, combining cutting-edge spraying and coating technologies. Designed to improve the strength and appearance of molded pulp products, the system enhances both performance and aesthetic quality.

Product Description:

This advanced coating line enables the creation of coated pulp products using renewable sugarcane bagasse. The spray coating system ensures a consistent, high-quality finish with a focus on sustainable manufacturing practices.

Technical Parameters:

| Parameter | Specification |

|---|---|

| Material Used | Sugarcane Bagasse Pulp |

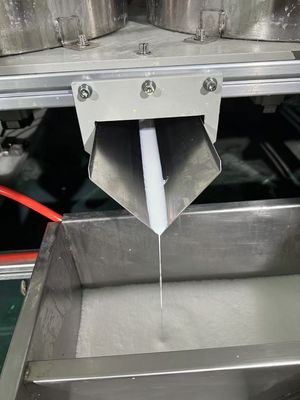

| Spray Coating Technology | Electrostatic Rotary Spray |

| Coating Material | Eco-friendly, Non-toxic Coatings |

| Production Output | 1000 - 3000 units/hour |

| Temperature Range | 30 - 60°C |

| System Control | Automated PLC Control with Touchscreen |

| Customizable Features | Yes, coating types and thickness |

Application:

-

Food Packaging: Safe, non-toxic coatings for food-grade packaging.

-

Cosmetic Packaging: Eco-friendly coatings for cosmetic containers.

-

Electronic Packaging: Sustainable packaging solutions for electronics.

Customization:

-

Adjustable coating viscosity for varying product types.

-

Tailored production capacity to suit factory needs.

-

Coating colors and textures can be customized.

Feature:

-

Automated cleaning cycle for low maintenance.

-

Compact and modular design for easy integration.

-

Suitable for high-throughput production without compromising quality.

-

Eco-friendly operation, aligned with sustainable manufacturing goals.

Support and Services:

-

Post-Sales Support: Lifetime technical support and spare parts availability.

-

Custom Engineering: Tailored engineering solutions for unique requirements.

-

Installation & Commissioning: On-site support for installation.

Packing and Shipping:

-

Packaging: High-quality packaging to prevent shipping damage.

-

Shipping: Global delivery with flexible shipping options.

FAQ:

-

How does the coating process enhance the pulp product?

-

The coating improves the durability, resistance to water, and appearance of the pulp product.

-

-

What types of coatings can be applied to the products?

-

The system can apply various eco-friendly coatings, such as water-based and UV coatings.

-

-

Can the production line handle large-scale manufacturing?

-

Yes, it is designed for both small and large-scale production environments.

-