Rotary Spin Coating System for Sustainable Pulp Molded Products

商品の詳細:

| 起源の場所: | 中国 |

| ブランド名: | OSMANUV |

| 証明: | ISO9001 |

| モデル番号: | OSM-XT-3200T |

| ドキュメント: | Version 2.0 of 24-station s...on.pdf |

お支払配送条件:

| 最小注文数量: | 1セット |

|---|---|

| 価格: | 交渉可能 |

| パッケージの詳細: | 木製パッケージ |

| 受渡し時間: | 60日 |

| 支払条件: | T/T |

| 供給の能力: | 交渉 |

|

詳細情報 |

|||

| 電圧: | 220V、380V、380V/220V、220V/380V、380V/50Hz | 状態: | 新しい |

|---|---|---|---|

| 提供されるアフターセールスサービス: | 海外の機械にサービスを提供できるエンジニア、ビデオテクニカルサポート、オンラインサポート、海外のサードパーティサポート利用可能、フィールドインストール | 寸法(l*w*h): | カスタマイズされたサイズ、2580*1130*1140mm、1000*2575*1750mm、1200*620*550mm(l*w*h)、1030*1000*620mm |

| 保証: | 1年、1年、12か月 | 力: | 3kW、16kW、65.3kW、4.2kW、0.75kW/220V/50Hz |

| 製品名: | 24ステーションスピンコーティングマシンライン | スピード: | 調整可能 |

| ハイライト: | rotary spin coating system for pulp molding,biodegradable film precision application machine,pulp molding coating machine with warranty |

||

製品の説明

Rotary Spin Coating System for Sustainable Pulp Molded Products

Composition of Production Line:

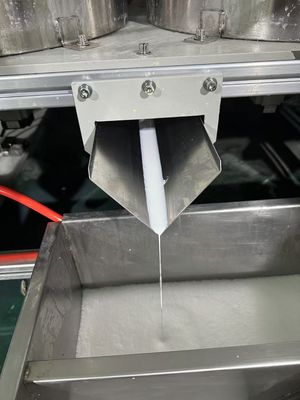

This precision line features a servo-driven indexing system, 24 individually programmable stations, high-precision ultrasonic spray or low-flow spray valves for minimal waste, a controlled climate pre-dry zone, a energy-efficient IR drying machine, and a final cooling conveyor.

Product Description:

This advanced rotary spin coating line is designed for applying the latest biodegradable, compostable, or UV-curable coatings to premium and sustainable pulp packaging. It focuses on precision application to minimize material usage—a critical cost factor for specialty coatings—while ensuring perfect performance. Ideal for high-value products in the electronics, cosmetic, and organic food sectors.

Technical Parameters:

| Parameter Category | Details & Specifications |

|---|---|

| Model | OSM-XT-3200T |

| Suitable Product | Premium Pulp Packaging, Electronics Trays, Cosmetic Containers |

| Number of Stations | 24 |

| Coating Technology | Programmable Ultrasonic Spray / Low-Flow Spin Coating |

| Coating Type | Biodegradable (PLA, PHA), Water-Based, UV-Curable |

| Curing Method | Customizable (UV-LED, NIR, or Low-Temp Hot Air) |

| Control System | Advanced PLC with IoT connectivity for data monitoring |

| Coating Weight Accuracy | ±2% |

Application:

Applying ultra-thin, functional barriers and aesthetic coatings to premium pulp molded products requiring home or industrial compostability certifications.

Customization:

Highly customizable based on coating chemistry. Options include ultrasonic spray heads for ultra-low viscosity materials, UV-LED curing for instant cure, or NIR for gentle drying of heat-sensitive biopolymers.

Feature:

- Precision Application: Ultrasonic spin coating technology drastically reduces overspray and material consumption.

- Sustainable Focus: Compatible with the latest bio-based and compostable coating formulations.

- Gentle Curing: UV-LED or NIR options prevent thermal degradation of sensitive pulp substrates.

- Data Tracking: IoT connectivity allows for monitoring of production metrics and quality control.

Support and Services:

Extensive application development support, partnership with coating material suppliers, and remote diagnostics.

Packing and Shipping:

High-precision spray valves are shipped in separate, shock-proof packaging. The entire system is covered for dust and moisture protection.

FAQ:

Q: Can this line handle very thin, water-based coatings without clogging?

A: Yes. The ultrasonic spin coating technology is specifically designed for low-viscosity, particle-free fluids and is far less prone to clogging than conventional air spray nozzles, ensuring consistent application and minimal maintenance.