|

詳細情報 |

|||

| フレーム素材: | ステンレス鋼/炭素鋼 | アプリケーション: | マテリアルハンドリング、梱包、組立ライン |

|---|---|---|---|

| 方向の運搬: | 左から右へ | ベルト材料: | PVC、ゴム、PU |

| 印刷物材料: | PLA、ABS | カスタマイズされた: | はい |

| ネットペーパー幅: | 1320mm | 材料: | ステンレス&PVC |

| ハイライト: | CNC自動化用5軸ガントリーロボット,繊細な部品ハンドリング用精密ロボット,コンベアベルト付きCNCローディング/アンローディング自動化 |

||

製品の説明

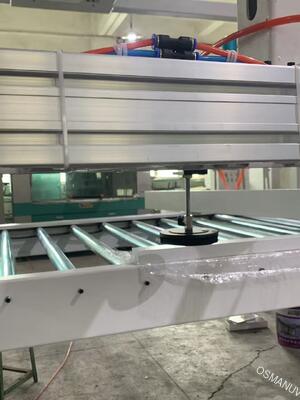

繊細な部品のハンドリングのための精密5軸ガントリーロボット - CNCロード/卸荷自動化

生産ラインの構成

精密なゲンターシステム 微量粒子生成材料 伺服力駆動線形モーター Z軸に搭載された5軸ロボットアーム 導航のためのビジョンシステムクリーンルームのプロトコルに対応する制御システム.

製品説明

この精密な5軸のゲントリロボットは 電子機器や医療機器や光学などの 繊細で高価な部品を扱うために 設計されていますマイクロンレベルの精度を提供し,クリーンルームに対応するバージョンで提供されています繊細な製品を汚染することなく,慎重で正確な操作を保証します.

テクニカルパラメータ

| パラメータ | 仕様 |

|---|---|

| モデル | GPR-Pシリーズ |

| 運動の軸 | 5軸 (X,Y,Z,R,傾き) |

| 位置付けの繰り返し性 | ±0.02 mm |

| 駆動技術 | 高性能線形モーター |

| クリーンルームの評価 | 任意のISOクラス5 (ISO 14644-1) |

| 制御システム | ビジョン統合付きの高度なモーションコントローラ |

| パイロード容量 | 10kgまで (カスタマイズ可能) |

| ガイドレールの材料 | ステンレス鋼またはセラミック (カスタマイズ可能) |

適用する

-

ワッフル,PCB,マイクロコンポーネントの積載/積荷

-

医療機器や光学機器の自動組成

-

精密テストと検査ステーション

カスタマイズ

このシステムは高度にカスタマイズできる応用できるのですカスタマイズするクリーンルームの認証,特定のビジョンシステムの統合,繊細な部品のための特殊なソフトコンタクトグリッパーを開発する.

特徴

-

準ミリメートル精度:線形モーターと高解像度のエンコーダは 卓越した精度を可能にします

-

クリーンルーム対応:厳格な清潔基準を満たすように設計されています

-

先進的な視力ガイド:商品の位置変化でも正確なピックと位置を保証します.

-

優しく操作するプログラム可能な力制御は 繊細なアイテムの損傷を防ぎます

-

データログ:完全な追跡性とSPCを確保するためにデータを処理します.

サポートとサービス

広範囲にわたるアプリケーションエンジニアリングサポート,現場の校正,検証文書 (IQ/OQ),および専門的なクリーンルームの設置手順を提供しています.

梱包と輸送

このシステムは クリーンルームの袋に詰め込まれ 慣性ガスで浄化され 輸送中に汚染や損傷を防ぐために カスタムデザインの箱に固定されます

よくある質問

-

Q: このロボットは 位置容量のある部品を操作できますか?

-

A: はい,統合されたビジョンシステムは,部品の位置を特定し,位置誤りを補正することができます.カスタマイズできるリアルなアプリケーションの機能です

-

-

Q: 繰り返し性と正確さの違いは何ですか?

-

A: 繰り返す能力は,学習した位置に一貫して戻る程度です. 精度は,実際のコマンド位置にどれだけ近いかを意味します. 私たちの精密モデルは,両方で優れています.オーダーメイドあなたのニーズに合わせて

-

-

Q:GMP環境の検証支援をしていますか?

-

A: はい,私たちは提供することができますオーダーメイド規制された産業の設置資格 (IQ) と運用資格 (OQ) をサポートする検証パッケージ

-