モールドパルプ用自動スプレーコーティングシステム | 精密内部コーティング

商品の詳細:

| 起源の場所: | 中国 |

| ブランド名: | Osmanuv |

| 証明: | ISO9001 |

| モデル番号: | OSM-ZDPT-1320PT |

| ドキュメント: | automatic spray coating mac...ne.pdf |

お支払配送条件:

| 最小注文数量: | 1セット |

|---|---|

| 価格: | 交渉可能 |

| パッケージの詳細: | 木製の箱 |

| 受渡し時間: | 30~45日 |

| 支払条件: | T/T |

| 供給の能力: | 交渉 |

|

詳細情報 |

|||

| 電圧: | 220V 50Hz | 色: | 青/緑/白 |

|---|---|---|---|

| 包装材料: | 木材 | 駆動型タイプ: | 電気 |

| コーティング材料: | ir | キーセールスポイント: | 高精度 |

| ランプ: | 台湾の石英加熱チューブを使用してください | コアコンポーネント: | エンジン、モーター |

| ハイライト: | automated spray coating system for molded pulp,precision internal coating machine,spray coating machine with warranty |

||

製品の説明

精密な内部コーティングです 精密な内部コーティングです

1生産ラインの構成

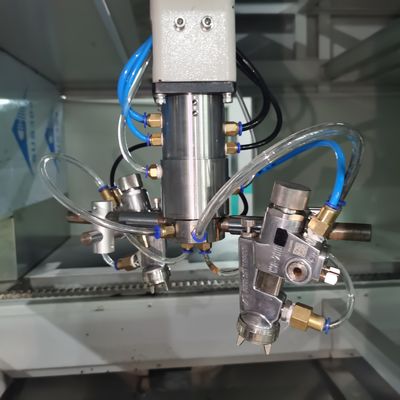

完全なシステムには:自動コンベア,高精度のスプレーガン付き6軸ロボットアーム,ビジョンポジショニングシステム,塗料循環と供給システム,PLC制御キャビネットが含まれます.

2製品説明

この自動スプレーコーティングシステムは,複雑な形状の鋳造パルプ製品の内部に水性バリアコーティングを適用するために設計されています.フィルムの厚さと完全なカバーを保証します材料の効率と製品の質を最大限に高めます

3. テクニカルパラメータ

| パラメータ | 詳細 |

|---|---|

| モデル | AS-MP500 (標準モデル)カスタマイズ可能) |

| ロボットタイプ | 6軸産業ロボット |

| 噴霧技術 | 高効率の空気補助空気なし |

| コーティングの均一性 | ±3%の偏差 |

| 位置付け 正確さ | ±0.5mm (視力システムによる) |

| 制御システム | PLC+タッチスクリーンHMI パスプログラム |

| 輸送機の速度 | 0.5〜3m/min (ロボットと同期) |

4適用する

水分や油脂を防ぎ 複雑な形状のボウルや貝殻やトレイなど 食品包装に使うのに最適です

5パーソナライゼーション

我々は提供します完全にカスタマイズできる塗料循環システムは,異なるコーティング粘度に対応できます.

6特徴

-

機械の精度で 100%の保全を

-

手動噴霧と比較して最大40%の材料削減です

-

視力導いた位置付けは,パルス製品の寸法変化を補償する.

-

閉ループ塗料システムで コーティング粘度と質を維持します

7サポートとサービス

ロボットコースプログラミングのトレーニングと 12ヶ月保証 24時間/24時間の技術サポートを提供しています

8梱包と輸送

このシステムはモジュールに分解され 天候に耐える木製のケースに詰められ 安全な輸送のために オーダーメイドの泡の挿入物があります

9よくある質問

-

Q: 異なる製品サイズをどのように扱うのですか?

-

A: システムは複数のスプレー経路を保存できます. HMI のレシピ選択によって変更が迅速です.カスタマイズ可能速速交換装置が用意されています

-

Q: 転送効率は?

-

A: 私たちの先進的なスプレー技術は 85%以上の転送効率を達成し 材料の廃棄物や過剰なスプレーを削減します