R&D 鋳造パルプの内部コーティングのためのスピンコーティング 実験室精密テストマシン

商品の詳細:

| 起源の場所: | 中国 |

| ブランド名: | Osmanuv |

| 証明: | ISO9001 |

| モデル番号: | OSM-XT-450T |

| ドキュメント: | Single-station spin coating...on.pdf |

お支払配送条件:

| 最小注文数量: | 1セット |

|---|---|

| 価格: | 交渉可能 |

| パッケージの詳細: | 木製の箱 |

| 受渡し時間: | 30~45日 |

| 支払条件: | T/T |

| 供給の能力: | 交渉 |

|

詳細情報 |

|||

| 状態: | 新しい | 自動グレード: | 半自動 |

|---|---|---|---|

| インクタイプ: | クイック乾燥 | 保証: | 1年 |

| 応用: | 食品パッケージ | 駆動型タイプ: | 電気、手動 |

| 包装材料: | 木材 | ||

| ハイライト: | 鋳造パルス用スピンコーター,ラボ精密スピンコーター,パルス・モールド・コーティング・マシン |

||

製品の説明

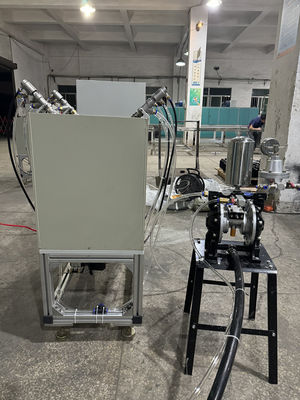

R&D 鋳造パルプの内部コーティングのためのスピンコーティング 実験室精密テストマシン

1生産ラインの構成

コンパクトなラボユニットには: プログラム可能なスピンコーター,サンプル固定用の真空チャック, 手動注射器配給器,統合ドリップトレイ,デジタル制御パネルが含まれます.

2製品説明

このR&Dスピンコーターは,内部コーティングの配列 (水に耐える,プレートや食品容器などの鋳造パルス製品精密なパイロットテストのために,フルスケール生産パラメータの正確なシミュレーションを可能にします.

3. テクニカルパラメータ

| パラメータ | 詳細 |

|---|---|

| モデル | SC-RD100 (標準モデル)カスタマイズ可能) |

| チャックサイズ | 標準100mm~300mm (完全 に 調整 できる) |

| 回転速度範囲 | 100〜8,000 RPM (プログラム可能) |

| 速度精度 | ± 1% |

| 試料の厚さ | 50mmまで |

| 制御インターフェース | レシピの保存付きの7インチタッチスクリーン |

| 電力 需要 | 110V / 220V,50/60 Hz (カスタマイズ可能) |

4適用する

鋳造されたパルプの食器,食品包装,および工業包装プロトタイプに障壁コーティング (水,油,油脂) を開発および試験するのに理想的です.

5パーソナライゼーション

我々は提供します完全にカスタマイズできる独自の鋳造されたパルプサンプル幾何学 (プレート,ボウル,トレイ) に適合する真空チャック設計.ソフトウェア機能と配給システムも調整できます.

6特徴

-

高精度なモーターで 繰り返すことができます

-

プログラム可能な多段階スピンプロファイル (加速,時間,速度)

-

実験室環境のための コンパクトで堅牢な設計

-

高価な製剤の試験に最適です

7サポートとサービス

ビデオ通話による設置指導,運用訓練, 12ヶ月保証,アプリケーションサポートが提供されています.

8梱包と輸送

ユニットは輸送中に損傷を防ぐために,泡から隔離された木製の箱に安全に梱包されています.航空または海で送料が可能です.

9よくある質問

-

Q:最小のサンプルサイズは?

-

A: A とオーダーメイド小型のチャックで 直径50mmのサンプルを処理できます

-

Q: 異なるコーティング粘度をテストできますか?

-

A: はい プログラム可能なスピン曲線により 様々な粘度層のパラメータを最適化できます